Energy Efficiency at TT-Line

CO2 reduction by utilization of waste heat on board of Robin Hood

The most pressing environmental impact from shipping, is the emission of greenhouse gases, especially CO2. In June 2021, IMO adopted key short-term measures aimed at cutting the carbon intensity of all ships by at least 40% by 2030.These measures combine technical and operational approaches to improve the energy efficiency of ships. By 2050, IMO intends to cut the carbon intensity by 70%, as compared to 2008.

The EU has committed to achieve climate neutrality by 2050.

It is evident that implementation of GHG neutral fuel is necessary, from both an environmental, climate and compliance perspective. But it is also evident that it will be years before we can rely purely on sustainable sources of energy. Therefore, we must constantly seek innovations in existing assets and ensure optimal energy efficiency, to keep the negative impact on environment as low as possible and reduce the overall energy cost.

Did you know that the main source of energy loss is in the engine?

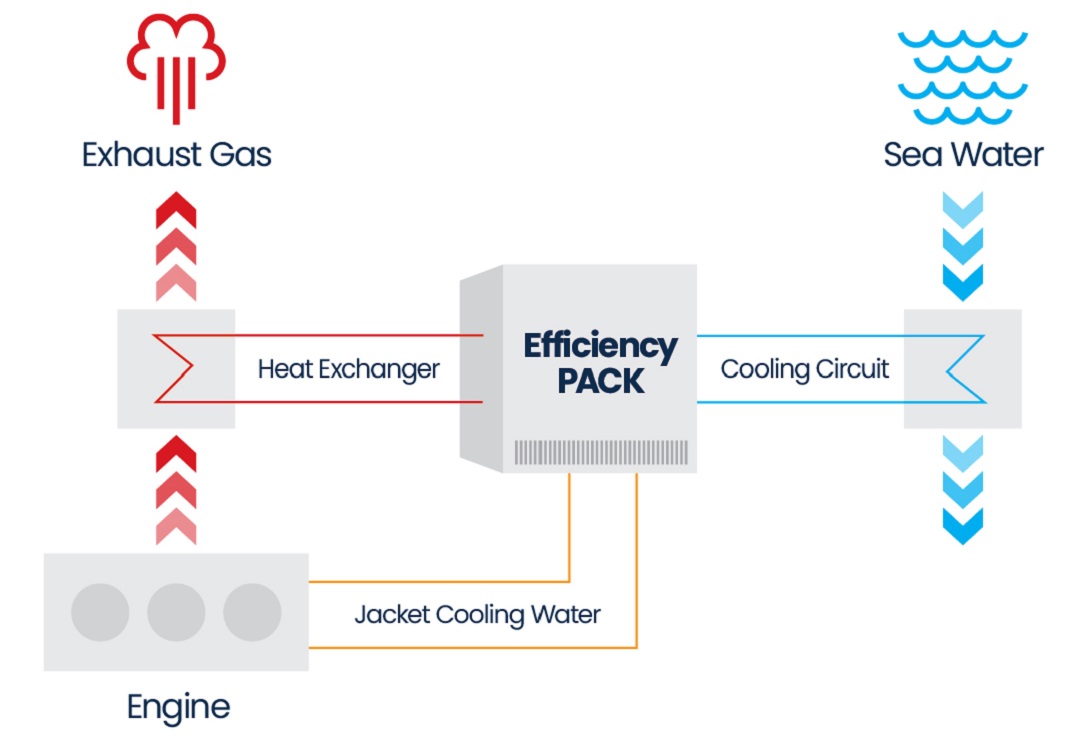

For that reason, the improvement of the engine efficiency can lead to significant reduction of the fuel consumption of a vessel. A considerable amount of heat is lost, mainly through the engine's jacket water cooling system and exhaust gases. About one half of the total waste heat is released through the exhaust gases. Additionally, among the different waste heat sources of the ship, the main engine exhaust gases are the most attractive due to their high exergetic content.

Sustainability at TT-Line

Learn more about our sustainable actions and our measures to protect the environment.

Our solution on board of Robin Hood

Considering the above, we have started a project to recover part of the energy in the exhaust gases by installing a Waste Heat Recovery device on board of our vessel Robin Hood and convert it into useful work by installing a special unit that works on Organic Rankine Cycle (ORC) during a planned yard stay in the year 2023.

Good to know: The name of the process goes back to the Scottish physicist and engineer William John Macquorn Rankine who lived and researched in the 19th century.

How does the Organic Rankine Cycle work?

The high temperature heat from the exhaust gases and low temperature heat from jacket water are the heat input to the ORC unit. The unit consists of an organic working fluid (non-toxic and non-flammable) which completes a cycle and continuously converts waste heat into mechanical work.

The waste heat enters the cycle via the evaporator and drives the ORC. In the evaporator the refrigerant is vaporized and routed to the expansion machine as superheated vapour. Here the highly pressurized refrigerant is expanded, thus releasing mechanical work, and driving the rotary screws in the expansion machine. This rotational energy is in turn used to drive a generator (included in the unit) that produces electricity. After the expansion machine the still gaseous refrigerant is liquified again in the condenser and the re-pressurized by the feed pump. The refrigerant has now completed the cycle and again enters the evaporator to absorb waste heat.

How does it help to save CO2 emissions in daily ship operations?

The energy output of the ORC system is converted into electricity to supply the on-board grid, without additional CO2 emissions.

The savings that will be achieved, are based on waste heat recovery, and thus are impacted by the operational profile of the vessel. Meaning the number of engines that are running and the load on the engines. Based on the regular engine operation and the potential electrical energy that can be generated, this results in an estimated annual fuel saving of about 3%. That doesn't sound like much?

Converted into CO2 savings, it adds up to more than 1.500 tons per year. Given the estimated hull life of 10 years, the total CO2 savings are expected to be more than 15.000 tons.

By comparison, the average CO2 footprint per capita in Germany is almost 11 tons, according to the German Federal Ministry for the Environment.

Source: BMUV

Production photos of actual units of Robin Hood